At Raydafon Compression, we engineer reliability. As a leading Chinese manufacturer specializing in oil-free diaphragm compressors, oil-free reciprocating compressors, and high-pressure air compressors, we power industries worldwide with cutting-edge gas solutions. Our expertise extends to advanced PSA oxygen generators and PSA nitrogen generators, crafted for sectors demanding uncompromising purity and performance.

RAYDAFON's ISO 8573-1 Class 0 certified oil-free air compressors set the global standard for critical clean air applications. Utilizing patented twin-screw and scroll technologies, these systems guarantee <0.01mg/m³ oil content with TÜV SÜD-verified monitoring. Engineered for 24/7 operations, our compressors deliver 7-350kW capacity ranges (10-500HP) with variable speed drives (VSD) that reduce energy consumption by 35% compared to fixed-speed models.

View MoreFor industrial operations demanding reliable compressed air, Raydafon Oil Injected Air Compressors deliver superior performance, energy efficiency, and durability. As a leading China-based manufacturer and OEM/ODM supplier, we provide high-quality compressors for wholesale, bulk orders, and customized applications.

Our oil-lubricated air compressors are engineered for heavy-duty use in manufacturing, automotive, construction, and more—ensuring smooth operation with minimal maintenance. Below, we detail key specifications, benefits, and expert insights to help you select the ideal compressor.

✔ 20+ Years of Manufacturing Expertise – Precision engineering for maximum output

✔ Strict Quality Control (ISO-Certified) – Each unit tested before shipment

✔ Competitive Factory Pricing – Direct-from-source savings for bulk buyers

✔ Fast Turnaround (15-30 Days Lead Time) – Reliable supply chain for urgent orders

✔ Custom OEM/ODM Services – Modify horsepower, tank size, pressure, and controls

Inquire Now for Customized Solutions!

| Model | Power (kW) | Airflow (CFM/m³/min) | Max Pressure (Bar/PSI) | Tank Size (L) |

|---|---|---|---|---|

| RD-15A | 15 | 58 / 1.65 | 10 / 145 | 500 |

| RD-30B | 30 | 125 / 3.54 | 12 / 174 | 800 |

| RD-75C | 75 | 320 / 9.06 | 13 / 188 | 1200 |

| RD-150D | 150 | 650 / 18.4 | 14 / 203 | 2000 |

Download Full Spec Sheet →

| Factor | Oil-Injected | Oil-Free |

|---|---|---|

| Lifespan | 15,000-20,000 hours | 8,000-12,000 hours |

| Maintenance | Oil changes every 2,000-4,000 hrs | Frequent part replacements |

| Noise Level | Quieter (65-75 dB) | Louder (75-85 dB) |

| Best For | Continuous industrial use | Hospitals, labs, light duty |

Pro Tip: For 24/7 operations, oil-lubricated models offer better longevity.

In critical applications requiring precision gas handling, Raydafon Special Gas Compressors deliver unmatched reliability and technical superiority. As a premier China-based manufacturer and OEM/ODM supplier, we engineer compressors specifically designed for wholesale buyers, customized industrial applications, and specialized gas processing needs.

✔ 25+ Years of Gas Compression Expertise

✔ ISO 9001 & CE Certified Manufacturing

✔ Custom-Built Solutions for Unique Gas Properties

✔ 45-Day Average Lead Time (Faster Than Industry Standard)

✔ Direct Factory Pricing (30% Lower Than Competitors)

Request Custom Specifications Today →

| Model | Flow Rate (m³/h) | Max Pressure (Bar) | Power (kW) | Gas Compatibility |

|---|---|---|---|---|

| SG-300 | 300 | 25 | 55 | N₂, O₂, Ar, CO₂ |

| SG-750 | 750 | 40 | 110 | CH₄, H₂, He |

| SG-1500 | 1500 | 60 | 220 | NH₃, Cl₂, Specialty Gases |

Download Full Engineering White Paper

| Factor | Special Gas Compressor | Standard Air Compressor |

|---|---|---|

| Materials | High-grade alloys for gas compatibility | Standard cast iron/aluminum |

| Safety Features | Leak detection, explosion-proofing | Basic pressure switches |

| Precision | ±0.5% flow control | ±5% variance acceptable |

| Typical Applications | Petrochemical, semiconductor, medical | General manufacturing |

Expert Insight: For hydrogen or oxygen service, specialized compressors prevent combustion risks through patented sealing systems.

For industries requiring clean, compliant emissions control, Raydafon After Treatment Equipment delivers cutting-edge performance with robust engineering. As a leading China manufacturer and OEM/ODM supplier, we specialize in high-efficiency aftertreatment systems for wholesale buyers, customized industrial applications, and global environmental compliance.

Our aftertreatment solutions help reduce harmful emissions (NOx, PM, CO) while improving engine efficiency—ideal for diesel engines, generators, marine applications, and heavy machinery. Below, we detail key product specifications, benefits, and expert insights to guide your selection.

✔ 15+ Years of Emission Control Expertise – Engineered for durability and efficiency

✔ ISO 9001 & CE Certified Manufacturing – Ensured reliability and performance

✔ Short Lead Times (20-35 Days Standard) – Faster than industry average

✔ Customizable Designs – Modify catalyst size, DPF materials, or control systems

✔ Competitive Factory Direct Pricing – Save 30-50% vs. Western brands

Request a Free Quote Today!

| Model | Flow Capacity (m³/h) | Max Backpressure (kPa) | NOx Reduction (%) | PM Filtration (%) | Compatible Engines |

|---|---|---|---|---|---|

| AT-200 | 200 | 25 | ≥90% | ≥95% | 50-150 kW |

| AT-500 | 500 | 30 | ≥92% | ≥97% | 150-300 kW |

| AT-1000 | 1000 | 35 | ≥95% | ≥99% | 300-600 kW |

Download Full Product Catalog →

| Feature | Aftertreatment System | Standard Exhaust |

|---|---|---|

| Emission Control | Reduces NOx, PM, CO by 90%+ | No significant reduction |

| Regulatory Compliance | Meets Euro VI, EPA Tier 4 | Non-compliant |

| Maintenance | Automated regeneration | Manual cleaning |

| Engine Efficiency | Optimizes combustion | No performance boost |

Key Insight: Aftertreatment systems are mandatory for industries needing to meet EPA, EU Stage V, or IMO Tier III regulations.

View MoreFor over 20 years, RAYDAFON has redefined excellence in pneumatic technology by merging rigorous engineering with relentless innovation. As the backbone of industries worldwide, our systems empower manufacturers to achieve unmatched operational efficiency while maintaining the highest quality standards.

The characteristics determined by the partial pressure of water vapor in compressed air and the temperature of compressed air are used for cooling, dehydration and drying. While keeping the compressed air pressure basically unchanged, lowering the temperature of the compressed air can reduce the water content in the compressed air, and the excess water vapor will condense into liquid. The refrigerated dryer uses this principle to dry compressed air using refrigeration technology, so the refrigerated dryer has a refrigeration system. CMN has such perfect refrigerated air dryers for sale. CMN refrigerated air dryers for air compressor are not only efficient in the working process but also cost-effective. Please CONTACT US.

The high-pressure micro oil screw air compressor crafted by CMN has an air supply pressure of 20 to 45 kg. The air end is lubricated with high-quality lubricating oil and has two stages screw compression air end, which can be adapted to most high-pressure compressed air supplies.

CMN oilless scroll-style air compressor has an air supply pressure of 2 to 12 bar, a gas production volume of 255 to 1660L/min, and an ultra-quiet design. As one of the best oil free compressor suppliers, CMN oilless scroll style compressor is suitable for various processes with small gas consumption but high cleanliness requirements. The main components of the unit are a high-precision square air end, permanent magnet motor, frequency converter, and stainless steel gas storage tank.

The working principle of the pure oil-free screw compressor is the same as that of the normal pressure oil-free screw air compressor. The difference is that the low-pressure screw air compressor is equipped with a low-pressure stainless steel air end with a compression ratio of 1.2 to 4, and the air supply pressure of the unit is 1.2 to 4 bar. The unit has good stability and low energy consumption.

The air storage tank can store a certain amount of compressed air, to make sure that the pressure of output air is relatively stable. It can also reduce the temperature in the air path and remove some water, dust, and impurities. The air storage tank is made of high-quality materials(carbon steel or stainless steel) and uses advanced welding technology. CMN air receiver tank for sale has passed ISO9001 certification and can pass any safety inspection.

Thermal adsorption type - uses part of the dried compressed air to purge the adsorbent after decompression to achieve "regeneration" of the adsorbent; Microthermal adsorption type - the difference from the non-thermal adsorption type is that the compressed air used for purging is heated by an electric heater.

CMN oil-free carbon dioxide reciprocating compressor, the air end is made of 304 stainless steel. If there are special requirements for the co2 screw compressor, 316 stainless steel can also be used to prevent corrosion. The inlet pressure, outlet pressure, and exhaust volume can be designed as required.

Coalbed methane compressor are mainly devices with water injected screw compressors as the air end, which are used in coal mine gas recovery, natural gas secondary recovery, oil fields, refineries, natural gas chemical plants, vinylon plants, chemical fiber plants and other petrochemical enterprises , as well as combustible gas recycling at liquefied gas stations and strategic combat readiness oil depots.

This product can not only recycle energy, but also significantly reduce environmental pollution. It has reliable quality, good cost performance, and is highly competitive in the domestic market. So far, coalbed methane recovery devices have been promoted and applied in petrochemical enterprises such as oil fields, refineries, natural gas chemical plants, vinylon plants, and chemical fiber plants. As a natural gas compressor manufacturer, CMN provides excellent compressors that effectively reduce pollution.

Relying on the low operating temperature of the air end, CMN, the hydrogen compressor manufacturers and suppliers, has developed a unique screw hydrogen compressor with a flow range of 5 to 59m3/min and a pressure range of 4 to 45bar. Since water is directly injected into the air end for compression, the operating temperature of the host will usually not be higher than 45 degrees Celsius, so safety can be guaranteed.

The advantages of the CMN oil-injected screw compressor are reflected in its outstanding energy-saving effect and variable frequency performance. The unit is equipped with a high-efficiency permanent magnet variable frequency motor and variable frequency drive, which automatically adjusts the speed to reduce energy consumption. Maintenance only requires replacing the filter element and air compressor oil. The CMN oil-injected screw air compressor is designed with no wearing parts, making maintenance simple and the designed service life is more than 20 years.

CMN oil-free high-pressure screw air compressor, with an air supply pressure of 20 to 40 bar, can be adapted to high-standard gas processes such as PET bottle blowing and blow molding. The whole high-pressure oil-free air compressor does not contain any lubricating oil to ensure that the outlet compressed air is oil-free. The screw-type air end performs two-stage compression with low vibration and noise. As one of the best oil free compressor suppliers, CMN oil-free high-pressure air compressor adopts an advanced two-stage dual-drive design and is equipped with two permanent magnet variable frequency motors with an efficiency of up to 97%. The inverter drive always supplies air with optimal efficiency. Maintenance is simple, only the air filter and water filter need to be replaced, reducing maintenance costs by 50% to 80%.

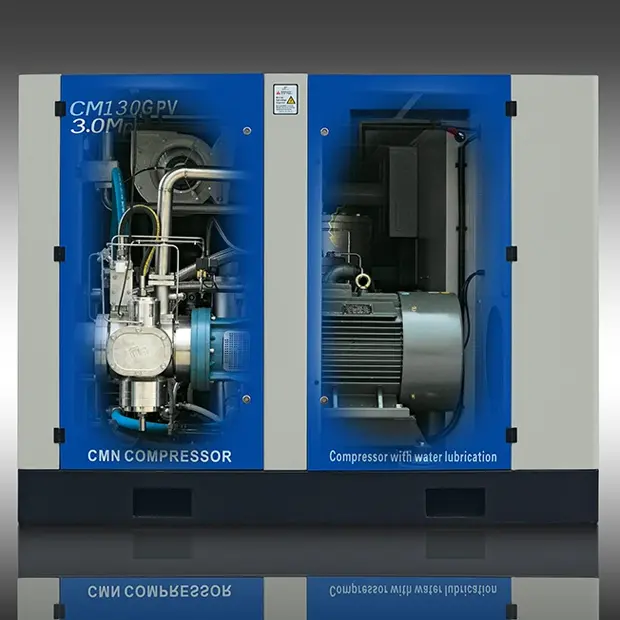

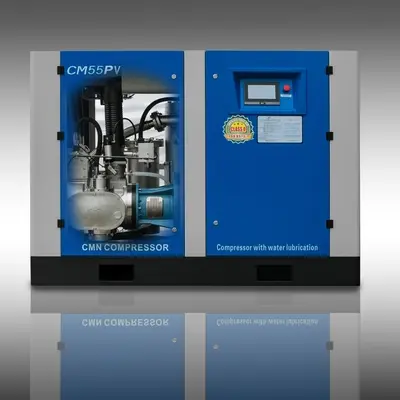

Pure water instead of lubricating oil is used in the air end for lubrication. The air end and all parts in contact with water are made of 304 food-grade stainless steel. Compressed air passes the TUV oil-free test and also meets the requirements of the FDA and GMP. With no oil in the whole water-injected screw compressor, maintenance is simple and only requires the replacement of the air and water filter. Water-injected screw compressor adopts a direct coupling method between the air end and the motor, resulting in high transmission efficiency. The water-injected compressor unit operates at an exceptionally low temperature, typically around 45 degrees Celsius, ensuring efficient cooling and energy use.

At Raydafon Compression, we engineer reliability. As a leading Chinese manufacturer specializing in oil-free diaphragm compressors, oil-free reciprocating compressors, and high-pressure air compressors, we power industries worldwide with cutting-edge gas solutions. Our expertise extends to advanced PSA oxygen generators and PSA nitrogen generators, crafted for sectors demanding uncompromising purity and performance.

Read More